|

|

Old Richmond, Virginia stucco building has

been painted, and has a series of sloppy patches over the

years. It is a cool design, and deserves

a facelift.

|

Areas under the windows were

never reinforced very good and were loose. Patches are torn

out and walls are chipped about every 2-3 inches to leave

the surface rough and the pores of the old stucco basecoat

open for a good bond.

|

|

|

| A scratch coat is applied

using plenty of acrylic in the mortar. We used Flex-con

half and half with water in the mortar for good

adhesion. |

A double up coat is applied the same

day. Here,

the thin brown coat is rubbed with a rubber float

to leave the surface nice and rough for a good

bond of the color coat. |

|

|

|

Metal lath is nailed on for

reinforcement of the window returns. A two by four is used

to form theoutside corner. 2 by strip is supported using

"legs" made from scrap furring strips.

|

Wall is filled to the strips

and straightened around

the legs.

|

|

Two by four form is removed forming a neat, straight line.

Bottom of window return is filled, and holes left by the

legs are filled, too.

Next step is to true up the bands.

|

|

|

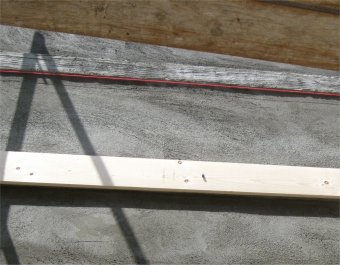

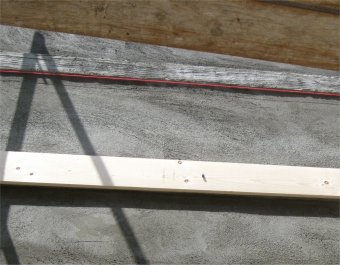

Here a string line is pulled

across the front of the building to align the bands and to

form a straight line.

|

One by sixes are set using

the string line.

The one by sixes proved to be the perfect width for this.

|

|

|

The bands are all formed and

the edges filled at the same time. After the one by's are

pulled off, we have a nice straight band.

|

Bands are finished first.

Grey color is made using white portland and white sand and

black paint colorant from Sherwin Williams. These colors are

organic and non toxic.

|

|

|

| Finish is

"Colonnade" Color 258 is from Expo stucco in

San Diego. We used our own recipe of White portland, lime,

and silica sand for crack resistance, color retention and

strength. |

Numbers for address are cast

using the "colonnade" mortar. Jaime cut wood numbers in his

shop to make the molds. |

|

Numbers are stuck using the finish mortar with pure Flex-con

and no water for strong adhesion.

Here the numbers are supported using two nails each until

the mortar sets up.

|

|

Coping, (flashing on the top

of a parapet wall is called coping) is bent using my metal

brake, and installed on the finished wall. Coping is

essential to ensure the wall will last. Stucco will last

forever as long as no water gets behind the stucco. |

|

|

| Panel surrounding the numbers

is taped off and finish coated. The finish is thick enough

to embed the numbers, making sure they will never come off. |

Another beautiful stucco

building.

Larger image here |