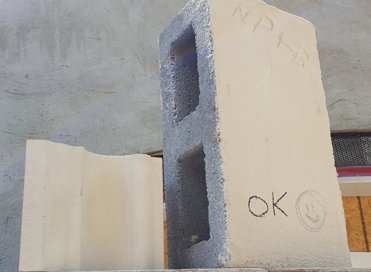

Most of the front was scored to look like limestone blocks.

Please keep reading for more details.

⇉ MORE DETAILS HERE ! ⇇

Please keep reading for more details.

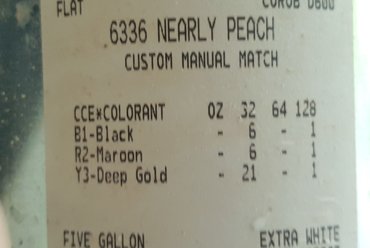

Nearly Peach is softened by using 6/32 oz. of black for a 5 gallon formula.

This beats the quarter inch thick one coat garbage they put on new houses. It's sad to see 6 year old

houses already falling apart.

The walls must be straight for this to work.

Screeds are set with a string line.

We don't use metal corner beads made for interior plaster.

Joints are taped and the inside of window and door openings are wrapped.

Weep grounds and weep screeds control expansion by letting water out of the stucco.

Floppy foam finger points the way.

Finish mortar is colored using paint tint.

We stuccoed this wall and the steps for a fraction of what it costs

to tear it out and rebuild.

Old stairs are leveled up.

Warning: You can starve to death waiting for a pizza delivery.